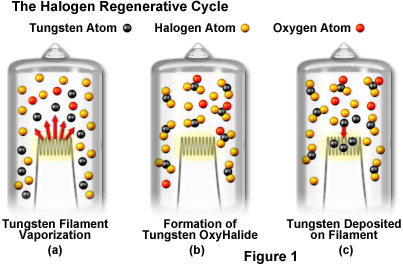

The tubular envelope in tungsten-halogen lamps is filled with an inert gas (either nitrogen, argon, krypton, or xenon) that is mixed during assembly with a minute amount of a halogen compound (usually hydrogen bromide; HBr) and trace levels of molecular oxygen. The halogen compound serves to initiate a reversible chemical reaction with tungsten evaporated from the filament to yield gaseous tungsten oxyhalide molecules in the vapor phase. Thermal gradients formed as a result of the temperature differential between the hot filament and the cooler envelope contribute to interception and recycling of tungsten to the lamp filament through a phenomenon known as the halogen regenerative cycle (illustrated in Figure 1). Thus, vaporized tungsten reacts with hydrogen bromide to form gaseous halides that are subsequently re-deposited onto cooler areas of the filament rather than being slowly accumulated on the inner walls of the envelope. This interactive tutorial demonstrates how halogens combine with tungsten and oxygen to complete the halogen regenerative cycle in incandescent tungsten halogen lamps.

The tutorial initializes with an animation of the halogen regenerative cycle occurring in a lamp that is cycling between room temperature at 2800° C. To operate the tutorial, click on the Stop Loop button, and move the slider back and forth to view various stages of the cycle.

The halogen regenerative cycle can be dissected into three critical steps that are outlined in Figure 1. At the start of operation, the lamp's envelope, fill gas, vaporous halogen, and filament are initially in equilibrium at room temperature. When power is applied to the lamp, the filament temperature rises rapidly to its operating temperature (in the vicinity of 2500 to 3000° C), a process that also heats the fill gas and the envelope. Eventually, the envelope achieves its stable operating temperature, which ranges from 400 to 1000° C, depending upon the lamp parameters. The temperature differential between the filament and the envelope creates thermal gradients and convection currents in the fill gas. Once the envelope reaches a temperature of approximately 200 to 250° C (depending on the nature and amount of halogen vapor), the halogen regenerative cycle begins. Tungsten atoms evaporated from the filament (see Figure 1(a)) react with gaseous halogen vapor and the trace levels of molecular oxygen to form tungsten oxyhalides (Figure 1(b)). Instead of condensing on the hot inner walls of the envelope, the oxyhalide compounds are circulated by convection currents back to the region surrounding the filament where they decompose, leaving elemental tungsten re-deposited on the cooler regions of the filament (Figure 1(c)). Once free of combined tungsten, the oxygen and halide compounds diffuse back into the vapor to repeat the regenerative cycle. Continuous recycling of metallic tungsten back and forth between the vapor phase and the filament maintains a more uniform wire thickness than would otherwise be possible.

The benefits of the halogen regenerative cycle include the ability to use smaller envelopes that are maintained in a clean, deposit-free condition during the life span of the lamp. Because the envelope is smaller than those used in conventional tungsten lamps, expensive quartz and related glass alloys can be more economically employed during fabrication. The stronger quartz envelopes enable higher internal gas pressure to be used to assist in suppression of filament vaporization, thus allowing increased filament temperatures that produce more luminous output and shift emission profiles to feature a greater proportion of the more desirable visible wavelengths. As a result, tungsten-halogen lamps retain their original brightness throughout their life span and also convert electric current to light more efficiently than their predecessors. On the downside, the tungsten vaporized and re-deposited by the halogen regenerative cycle is not returned to its original location, but rather winds up on the coolest regions of the filament, resulting in uneven thickness. Eventually the lamps fail due to decreased filament thickness in the hottest regions. Otherwise, tungsten-halogen lamps might feature almost infinite life spans.

Contributing Authors

Tony B. Gines and Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.